1. Profile:

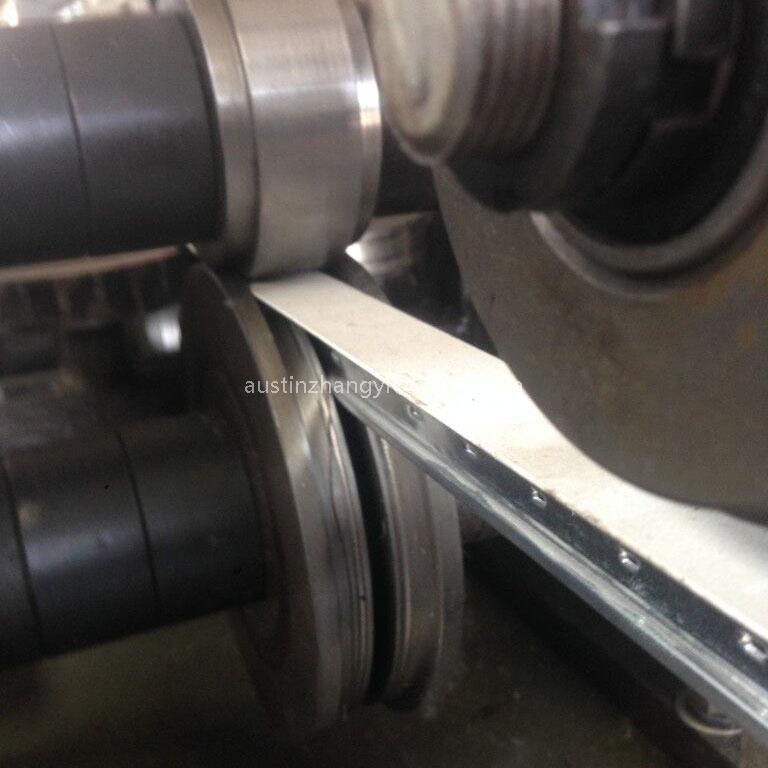

1.1 Profile thickness: 0.4mm, 88-90mm

Facing thickness: 0.25mm (cap), 29-30mm

1.2 Specification: per given

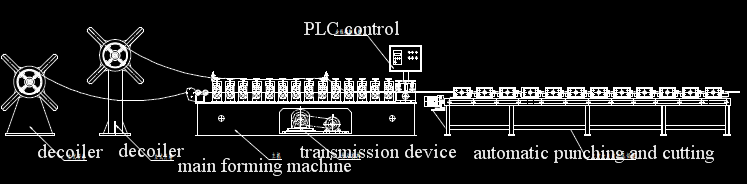

2. Process

De coiling—roll forming---hydraulic punching and cutting---product table

3. two pieces 1.5T Manual De-coiler

3.1 max carrying capacity: 1500kg

3.2 Two pieces of dec oiler

bigger one for profile material,

smaller one for facing material

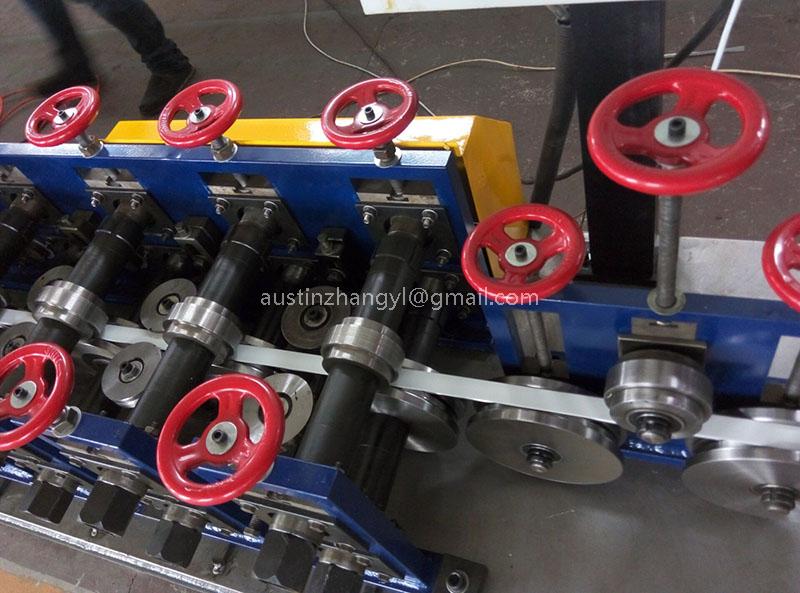

4. Roll Forming Machine

4.1 Shaft diameter 40mm

4.2 Roller Material: Cr12

4.3 Stations: 14 stations

4.4 Transmission: gear wheel

4.5 Forming speed: 30m/min

4.6 Motor: 4kw

4.7 Structure: independent stand

4.8 Voltage, Frequency,Phase: 380V, 50Hz, 3Phase

4.9 ink covering and air drying device

5. Automatic Punching and Cutting

5.1 Hydraulic power: 15kw

5.2 Punching unit : 12 cylinders & 12 pairs of mold

5.3 Main tee punching can do 3600mm main tee middle holes and end locks